>> Automated & efficient cleaning of all your dairy, juice or drink production equipment

|

Item |

Option 1 |

Option 2 |

Option 3 |

Option 4 |

|

Nbr of Lines |

1 |

2 |

3 |

4 |

|

Nbr of Tanks |

4 |

5 |

5 |

5 |

|

Type of Tank |

1 Tank with 4 compartiments |

Separate Tank |

Separate Tank |

Separate Tank |

|

Tank Capacity |

1.500 L |

2.000 L |

5.000 L |

10.000 L |

|

Forward pump capacity |

15.000 L/Hr |

20.000 L/Hr |

25.000 L/Hr |

25.000 L/Hr |

|

Sanitation |

Yes |

Yes |

Yes |

Yes |

|

Water Re-use |

No |

Yes |

Yes |

Yes |

It is important to note that equipment can be bacteriologically clean without necessarily being physically or chemically clean. However, it is easier to achieve bacteriological cleanliness as a matter of routine if the surfaces in question are first rendered at least physically clean.

Cleaning and sanitization of process plant is one of the most critical aspects of food processing to ensure the health and safety of consumers. Proper cleaning is essential for the production of high quality food products, especially those with extended shelf life. The quality department is in charge of entering the required settings inside the CIP and monitoring the cleaning results.

CIP is considered such as utility equipment. Steam, water, compressed air and electricity are necessary for CIP to work. The technical department is in charge of providing utilities for CIP to work and of maintaining the CIP system in good shape.

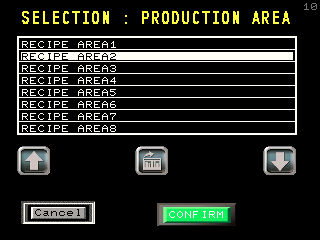

Operators are the persons running the CIP most of the time. They choose equipment they want to clean and the type of cleaning. The process department is running the CIP.

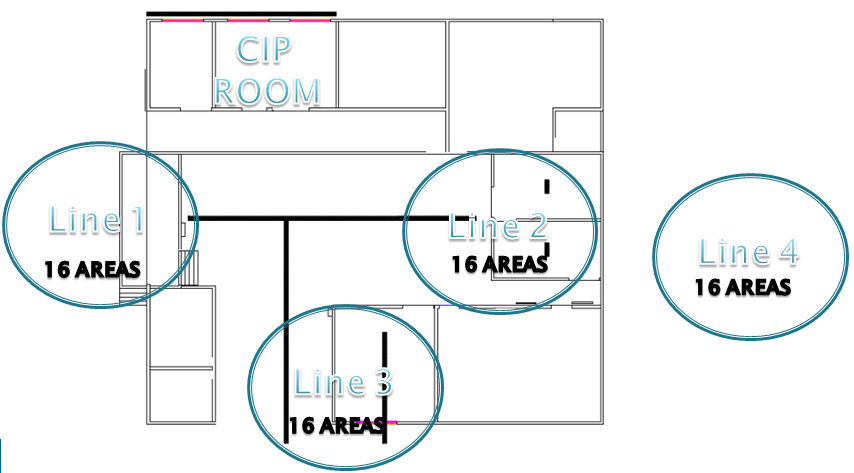

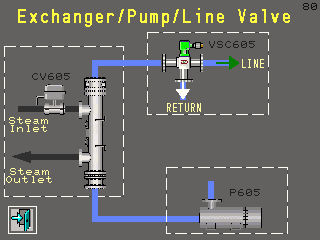

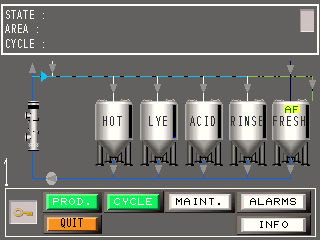

The main part of the CIP is located in the utility room of the factory, the CIP network is going all over the factory in production to clean all types of equipment such as tanks, exchangers, trucks… The CIP is equipped with 4 lines, each line can clean an area composed of up to 16 pieces of equipment.

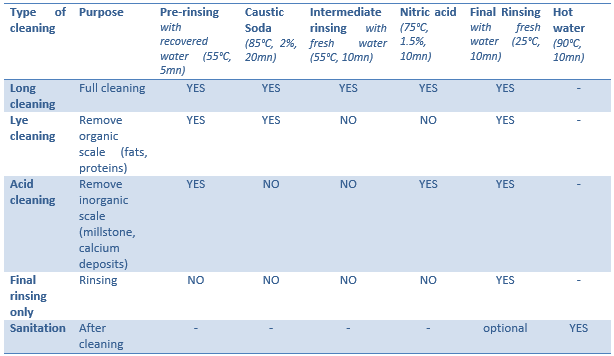

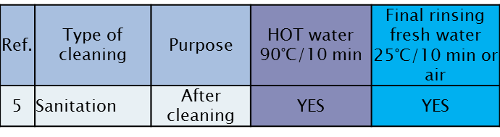

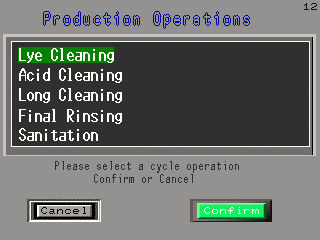

Depending on equipment to clean, there are several cleaning program available in our system:

After a detergent cycle, the fresh water used as post-rinse and the terminal sanitizers are collected and re-used as pre-rinse for the next CIP cycle. This saves both water usage and effluent treatment costs.

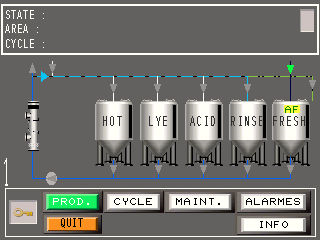

>> Our program display is intuitive, friendly designed and easy to run.

Our CIP system contains password that allow trained people to go in advanced parameters.

For operators that are only running CIP in auto mode, the system is really easy to run:

Then they can monitor the status of cleaning on the screen.

>> Improvements and innovation for CIP

Not only ALPES provides you tailormade solutions for CIP system( hot water tank, partitioned or separated tank, agitator Y/N,…) but also keeps innovating. In addition with the basis solution, Alpes is developing a recording system to offer the possibility to survey the main parameters in a logbook:

Alpes proposes forward flow detection for both:

We can study any of your specific requests, do not hesitate to contact our engineering unit.

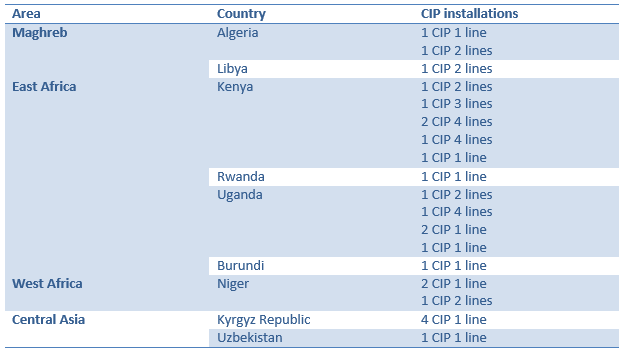

>> ALPES CIP installations in the world

Contact us today, and we’ll be happy to help you to the next step.

Sales Department

WhatsApp

+7 962 272 00 03

WeChat

Equipment Department

WhatsApp

+33 6 70 57 63 84

WeChat

Spare parts Department

WhatsApp

+33 6 44 39 49 19

WeChat

© 2022 All Rights Reserved.